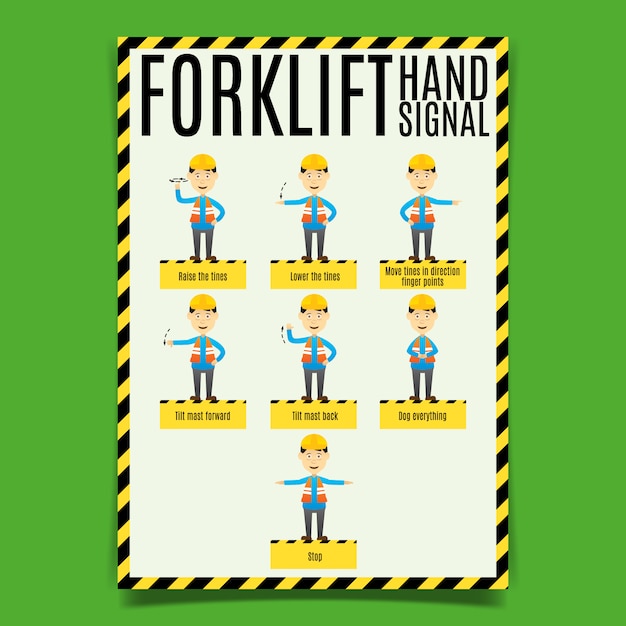

Point your index finger in the direction you want the tines to go. Signal to move the tines to the right or left by extending one arm out to the side (the arm nearer the direction the tines should move). Repeat the motion until the tines are where they should be. Keeping your arm extended, lower it to mid-chest.

Extend one arm out the side, palm facing down.

This signal is used when the load should be dropped. Point your index finger to the ceiling and make a circle with your hand and forearm until the tines are at the correct height. To signal raising the tines, hold one arm out to the side with your elbow bent 90 degrees. Raise the tinesĬommonly, a spotter will need to tell the operator to raise or lower the tines. These signals indicate what to do with the forklift’s tines (forks), mast and brakes. However, many jobsites adapt the hand signals OSHA uses for cranes and derricks. Wondering which forklift hand signals OSHA recommends? OSHA doesn’t have any requirements around forklift signals. Learning these signals should be part of ongoing forklift training. Utilizing the basic forklift and telehandler hand signals, especially when traveling around blind corners and any time the operator does not have a clear view of what’s in front of them, can help prevent material losses, injuries and even deaths. According to the National Safety Council, in 2020, forklifts were the source of 78 work-related deaths and 7,290 nonfatal injuries involving days away from work. That’s important because forklift accidents are too common. Forklift hand signals allow for clear communication between an operator and a forklift spotter, even in the loudest work environments.

0 kommentar(er)

0 kommentar(er)